Welcome to Our Company

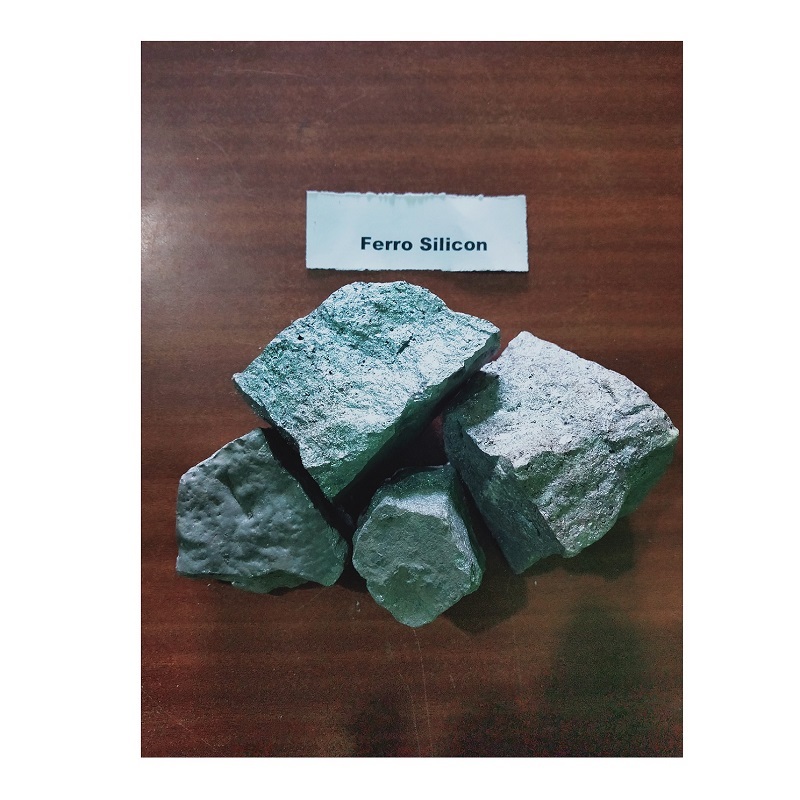

Ferro Silicon

197000.00 INR/Metric Ton

Product Details:

- Product Type Ferroalloy Products

- Alloy Ferro Alloy

- Shape Lump

- Size 10-60 mm

- Application Metallurgy, Steel Industry, Casting, Steel Making, Foundry, Iron Industry, Iron Casting

- Click to view more

X

Ferro Silicon Price And Quantity

- 197000.00 INR/Metric Ton

- 10 Metric Ton

Ferro Silicon Product Specifications

- 10-60 mm

- Ferro Alloy

- Ferroalloy Products

- Lump

- Metallurgy, Steel Industry, Casting, Steel Making, Foundry, Iron Industry, Iron Casting

Ferro Silicon Trade Information

- Kolkata Port

- Cash Against Delivery (CAD), Western Union, Paypal, Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- 50 Kg Jute bags and 1 Ton Jumbo bags

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America

- All India

Product Description

Ferro Silicon(FeSi) is an alloy of silicon and iron with a very high silicon content of between 10% and 90%. It is used as master alloy in steel manufacturing, which is added in small quantities in order to change the properties of the melt, the freezing process and the final product.

| Ferro Silicon (FeSi)- Size: 10 - 50MM; 25- 150 MM | ||||||||||

| Si | C | AI | P | S | ||||||

| 70% - 75% | 0.15% Max | 1.5% Max | 0.05% Max | 0.05% Max | ||||||

FAQs of Ferro Silicon:

Q: What is the application of Ferro Silicon in the metallurgy industry?

A: Ferro Silicon is commonly used in the metallurgy industry for various purposes such as deoxidizing, desulfurizing, and alloying of steel and iron.Q: How is Ferro Silicon beneficial in the steel industry?

A: In the steel industry, Ferro Silicon is used to improve the strength and quality of steel by enhancing its magnetic properties, corrosion resistance, and hardenability.Q: What role does Ferro Silicon play in the casting process?

A: Ferro Silicon is essential in the casting process as it helps in preventing the formation of graphite inclusions and improving the machinability and surface finish of the final cast products.Q: How does Ferro Silicon contribute to steel making?

A: Ferro Silicon is added to the steelmaking process to control the grain size and structure of steel, enhance fluidity during pouring, and reduce the presence of impurities like sulfur and oxygen.Q: What is the significance of Ferro Silicon in the foundry industry?

A: In the foundry industry, Ferro Silicon is used as a deoxidizer and inoculant to improve the mechanical properties and durability of cast iron products.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email