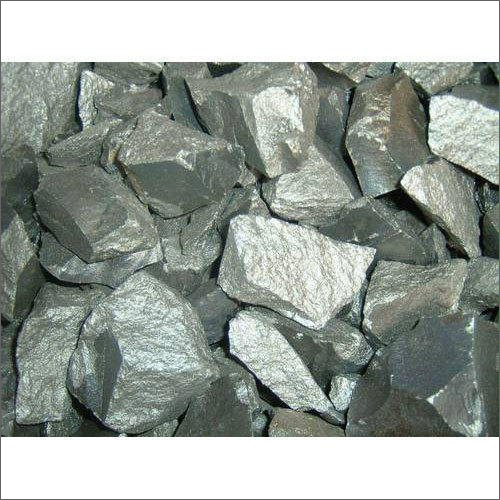

High Carbon Silico Manganese

Product Details:

- Product Type Ferroalloy Products

- Alloy Ferro Alloy

- Shape Lump

- Size 10-60 mm

- Application Iron Industry, Metallurgy, Iron Casting, Foundry, Steel Industry, Casting, Steel Making

- Click to view more

High Carbon Silico Manganese Price And Quantity

- 98000.00 INR/Metric Ton

- 10 Metric Ton

High Carbon Silico Manganese Product Specifications

- 10-60 mm

- Ferro Alloy

- Iron Industry, Metallurgy, Iron Casting, Foundry, Steel Industry, Casting, Steel Making

- Lump

- Ferroalloy Products

High Carbon Silico Manganese Trade Information

- Kolkata Port

- Western Union, Cash Against Delivery (CAD), Paypal, Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- 50 Kg Jute bags and 1 Ton Jumbo bags

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- All India

Product Description

An alloy called high carbon silico manganese contains significant amounts of carbon, manganese, silicon, and iron. In the steel industry, it is primarily utilised as an alloying agent to improve the characteristics of steel.

| H.C Silico Manganese (Low Phos)- Size: 10/20 - 50/60/70/80 MM; 25 - 150 MM | ||||||||||

| Mn | Si | C | P | S | ||||||

| 65% -70% Min | 16% - 17% Min | 2.0% Max | 0.25% Max | 0.03% Max | ||||||

| 60% - 65% Min | 14% - 16% Min | 2.0% - 2.5% Max | 0.25% Max | 0.03% Max | ||||||

| 50% Min | 12% Min | 3.0-3.5% Max | 0.30% Max | 0.04% Max | ||||||

| 40% Min | 10% Min | 3.0-3.5% Max | 0.30% Max | 0.04% Max | ||||||

The characteristics and advantages of high carbon silica manganese are as follows:

Features of High Carbon Silico Manganese:

1. High Carbon Silico Manganese generally includes between 60 and 70 percent manganese, 10 to 20 percent silicon, 2 to 4 percent carbon, and trace amounts of other elements. Depending on particular requirements, the precise composition may change.

2. High Carbon Silico Manganese: The High Carbon Silico Manganeses high carbon content helps the steels overall strength and hardenability. Steel is more resistant to wear, deformation, and heat when carbon is added.

3. Steels mechanical characteristics are improved by the high manganese content of high carbon silico manganese. Steel becomes stronger, harder, and tougher when manganese is added, making it suited for demanding applications.

4. Contains Silicon High Carbon Silico Manganeses deoxidation and desulfurization properties are enhanced by silicons presence. Additionally, silicon improves the fluidity and castability of molten steel, which speeds up the casting process.

5. High Carbon Silico Manganese has a base element called iron that serves as the building block for the production of the alloy and the matrix for steel. It enhances the steels total tensile strength and ductility.

Benefits of High Carbon Silico Manganese:

1. High Carbon Silico Manganese is predominantly utilised as an alloying agent in the manufacture of steel. Steel gains improved strength, hardness, and toughness that make it more appropriate for uses that call for long-lasting and high-performance materials.

2. Increased Strength and Hardness: Steels strength and hardness are greatly increased by the high carbon and manganese content of High Carbon Silico Manganese. This makes it perfect for applications where wear resistance and hardness are crucial, such mining and construction machines.

3. Steel That Can Be Heat-Treated: Due to the high carbon concentration, steel that can be quenched and tempered is made from high carbon silico manganese. The steel can then be tailored to the appropriate application requirements and attain precise mechanical qualities.

4. Deoxidation and desulfurization: High Carbon Silico Manganeses silicon and manganese content support the deoxidation step in the steelmaking process, producing cleaner, higher-quality steel. Desulfurization, which lowers the steels sulphur content, also benefits from it.

5. Applications Across Industries: High Carbon Silico Manganese is used in a wide range of industries, including engineering, transportation, and construction. High-strength and wear-resistant steels are created using it for parts like crankshafts, axles, and gears.

High Carbon Silico Manganese is a useful alloy in the steel industry overall because it gives steel increased strength, hardness, and wear resistance. The manufacturing of high-performance steel for demanding applications, where hardness and endurance are essential, is aided by its usage as an alloying agent.

Specification

- Carbon: 2-3% Max

- Manganese: 60%

- Phosphorus: 0.03% Max

- Silicon: 14% Max

- Sulfur: 0.0.04% Max

- Country of Origin: Made in India

- Material: Durgapur

- Size: 10 to 50 mm

FAQs of High Carbon Silico Manganese:

Q: What is the primary alloy of High Carbon Silico Manganese?

A: High Carbon Silico Manganese is a Ferro Alloy.Q: In which industries is High Carbon Silico Manganese commonly used?

A: High Carbon Silico Manganese is widely utilized in the Iron Industry, Metallurgy, Iron Casting, Foundry, Steel Industry, Casting, and Steel Making.Q: What is the size range of High Carbon Silico Manganese?

A: The size of High Carbon Silico Manganese ranges from 10-60 mm.Q: What is the typical shape of High Carbon Silico Manganese?

A: High Carbon Silico Manganese is available in a lump shape.Q: How is High Carbon Silico Manganese typically used in the steel industry?

A: In the steel industry, High Carbon Silico Manganese is commonly used as a deoxidizer and desulfurizing agent in the production process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+