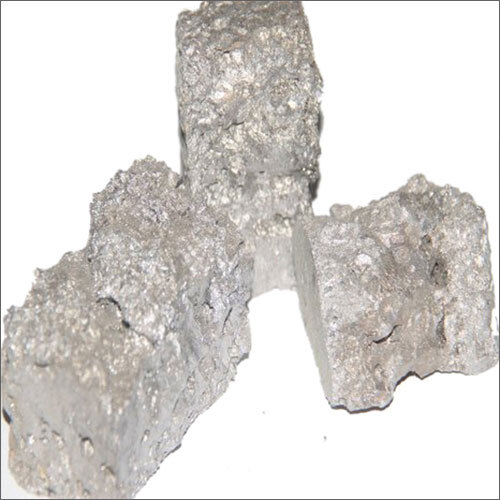

High Carbon Ferro Chrome

Product Details:

- Product Type Ferroalloy Products

- Alloy Ferro Alloy

- Shape Lump

- Size 10-60 mm

- Application Iron Industry, Steel Making, Metallurgy, Foundry, Iron Casting, Casting, Steel Industry

- Click to view more

High Carbon Ferro Chrome Price And Quantity

- 1192.00 USD ($)/Metric Ton

- 25 Metric Ton

High Carbon Ferro Chrome Product Specifications

- Iron Industry, Steel Making, Metallurgy, Foundry, Iron Casting, Casting, Steel Industry

- Ferro Alloy

- 10-60 mm

- Lump

- Ferroalloy Products

High Carbon Ferro Chrome Trade Information

- Kolkata Port

- Paypal, Western Union, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- 100 Metric Ton Per Day

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- 50 Kg Jute bags and 1 Ton Jumbo bags

- Australia, South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Africa

- All India

Product Description

Low Carbon Iron, chromium, and a significant amount of carbon (usually 6-8%) make up the alloy known as ferro chrome. In the process of making stainless steel and specialty steels, it serves as an alloying agent. The alloys high carbon content gives it more hardness and wear resistance. It increases corrosion resistance by aiding in the production of a protective oxide layer. In order to boost the chromium content of molten steel during the steelmaking process, HC FeCr is added. As a result, stainless steel has better corrosion, heat, and wear resistance. It is used in consumables for welding as well as cutting tools, dies, and wear-resistant parts. Applications requiring refractory materials can benefit from its high melting point and thermal stability. An important product in the ferroalloy market is HC FeCr.

| High Carbon Ferro Chrome-Size: 10 - 150MM; 10-100 MM; - 150 MM(HC FeCr) | ||||||||||

| Cr | Si | C | P | S | ||||||

| 57%-63% | 4% Max | 8% Max | 0.40% Max | 0.05% Max | ||||||

| 57%-63% | 4% Max | 8% Max | 0.020% Max | 0.05% Max | ||||||

| 57%-63% | 4% Max | 8% Max | 0.15% Max | 0.05% Max | ||||||

FAQs of High Carbon Ferro Chrome:

Q: What are the applications of High Carbon Ferro Chrome?

A: High Carbon Ferro Chrome is commonly used in the Iron Industry, Steel Making, Metallurgy, Foundry, Iron Casting, Casting, and Steel Industry.Q: What is the size range of High Carbon Ferro Chrome?

A: The size of High Carbon Ferro Chrome typically ranges from 10-60 mm.Q: What is the shape of High Carbon Ferro Chrome?

A: High Carbon Ferro Chrome is in lump form.Q: Is High Carbon Ferro Chrome classified as a Ferro Alloy?

A: Yes, High Carbon Ferro Chrome is classified as a Ferro Alloy.Q: Which industries benefit from using High Carbon Ferro Chrome?

A: High Carbon Ferro Chrome finds applications in the Iron Industry, Steel Making, Metallurgy, Foundry, Iron Casting, Casting, and Steel Industry.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+